Currently SEDISA operates a number of energy production facilities owned by others, taking care of both the functional aspect (operation and maintenance) and the administrative and legal.

SEDISA performs feasibility studies in industrial facilities to implement energy saving processes based on the use of alternative fuels, the introduction of more efficient systems or changes on the habits of production.

SEDISA, designs and erects any type of industrial installation, from the stage of pre-feasibility study to commissioning.

SEDlSA conducts environmental studies and the necessary procedures for obtaining Integrated Environmental Authorizations(IPPC).

Flowing hydroelectric plant, with a 4.5 MW Pelton turbine. Located at A Peroxa (Orense).

Modification of thermal energy utilizations of cogeneration plant for fiber board factory. Located in Nadela (Lugo)

Flowing hydroelectric plant, with one Crossflow turbine, 1,2 MW power. Located at São Pedro do Sul (Portugal).

Installation of a third turbine at the Ponteliñares hydroelectric power plant (Orense) for use of low flow rates.

Hydroelectric plant, with a 7.0 MW Francis turbine. Located at La Fernandina dam (Jaen)

Cogeneration plant with four natural gas engines of 3,65 MWe, recovery boilers for steam production, and ammonia absorption for chilled water production.

Cogeneration plant with four natural gas engines of 1,00 MWe and recovery boilers for steam production.

For PMA we have designed and built a plant for the separation of hydrocarbons in water, for the treatment of contaminated water from gas stations, bilge discharges, etc.

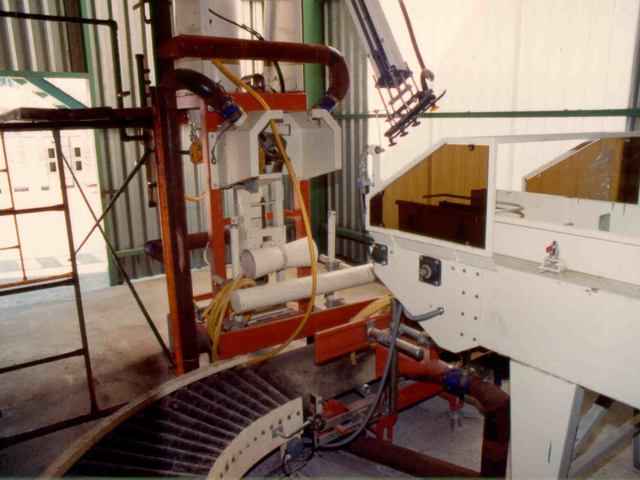

For REPSOL we design and build at Sabón (La Coruña), a plant for processing of petroleum coke from refinery, including drying, grinding, classification and storage.

At Puertollano refinery (Ciudad Real) we design and build a facility for the processing of sulfur by-product in the refining of petroleum.

For Ferroatlantica in their facilities at Sabón (La Coruña), among other works, we have built a pilot plant for the production of solar grade silicon used in the manufacture of photovoltaic panels.

Flowing hydroelectric plant, with two Francis turbines and a total 5 MW power. Located at Limia river (Orense)

For Caleras San Cucao we have developed multiple projects, most notably the drafting and management of its Integrated pollution prevention and control plan (IPPC), including extensions and technical projects for fuel switching in the furnace.

We have designed, built and operated a biomass generation plant in Cabra (Cordoba) with a power 8MWe, using waste (orujillo) from the extraction of olive oil.

Also in Cabra (Cordoba), we have designed, built and operated an "orujillo" drying plant with a cogeneration of 13MWe powered by a gas turbine and all associated ancillary facilities, liquefied natural gas, 132 kV substation, water sypply, etc.

We conducted an audit report for the analysis of the economic damage caused by legislative changes at Papelera de Brandia (Santiago de Compostela).

We have made many expert reports, including recent analysis of the economic damage caused by legislative changes in the wind farm operated by the Polytechnic School of La Almunia at Zaragoza.

Design and construction of a plant for the use of the red mud from bauxite processing at ALCOA aluminiun plant, the installation allows the manufacture of bricks for thermal storage inerting an hazardous waste.

We have prepared and managed the IPPC process for all PMA plants, including its recovery plant, waste transfer center, used tires (NFU's) processing installation, plastics recovery plant and oil filters and containers recovering facilities.

We have prepared and managed the IPPC project for all Bioenergetica Egabrense installations, including drying plant, biomass generation plant, Liquefied Natural Gas storage 132 kV substation and line, ancillary facilities, etc.

For Tafiber, a company dedicated to the manufacture of fibreboard, we have developed several projects for the reduction and management of wastewater, including combustion and condensation installations, decantation, as well as the design and project management of its submarine outfall in Betanzos estuary.

For the company Canal de Isabel II we have carried out the rehabilitation project of Navallar hydroelectric plant.

For the company Canal de Isabel II we have carried out the project for installation of a new turbine Pelton at the historic Torrelaguna hydro plant.

For the company Hidrosca we designed and built in the Huesca Pyrenees the Gorgol hydroelectric plant with a 4 MW Pelton turbine.

For IP Hidroenergias Pisões Lda we build and operate the Pisões hydroelectric power plant with a 1 MW Pelton turbine near Amarante (Portugal).

For the company Hidroeléctrica Lumymey we designed and built in Santiso (La Coruña) a solar photovoltaic installation of 100 kW.

For the public company Mancomunidad de los Canales del Taibilla we have managed for several years the maintenance of its hydroelectric power plants, three Pelton groups and one Perga with a combined power of 1 MW.